VMQ Silicone

VMQ resin, consisting of methyl groups and vinyl groups, has a variety of application industries: silicone rubbers in the automotive industry, food processing, silicone elastomers, flame retardants, and high and low-temperature applications.

Table Of Content For This Page

To make sure you can find the information you want quickly,

we have prepared this content directory that will jump to the corresponding location when you click on it.

01.

Applications

02.

Buyer Guides

03.

About VMQ Silicone

04.

Factors Consideration

05.

About XJY Silicone

06.

Clients' Feedbacks

07.

FAQs

08.

Related Products

General Applications For VMQ Silicone

VMQ resin, consisting of methyl groups and vinyl groups, has a variety of application industries: silicone rubbers in the automotive industry, food processing, silicone elastomers, flame retardants, and high and low-temperature applications. Depending on the M:Q ratio, the chemical resistance properties, specifications and applications differ.

How To Choose Silicone VMQ Products?

Based on customer feedback, the following are our recommended products for some typical applications. Please contact us if you have further questions.

Silicone Defoamer

- XJY-8205D

Silicone Release Agent

- XJY-8205D

Silicone Release Agent

- XJY-8205D

Silicone Defoamer

- XJY-8205D

What Is VMQ Silicone ?

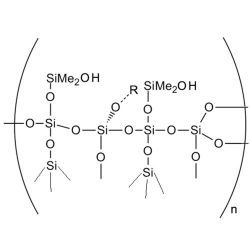

VMQ silicone resin is a new type of resin with a three-dimensional (non-linear) structure consisting of SI-O bonds as the backbone of its molecules. VMQ silicone polymers are unique compounds that have excellent resistance in industries due to introducing a vinyl group, a reactive group, into the silicon atoms of a methyl silicone resin.

01.

High-temperatures Resistance

Excellent heat resistance, hot air resistance and can be used in -60℃ to 300℃ temperature range

02.

Excellent Physical Properties

Good film formation, adhesion, low-temperature flexibility, and excellent resistance to aging, UV radiation, animal and vegetable fats and transmission oils.

03.

Water Resistance

Excellent water repellency, tear-resistance and low toxicity.

04.

Silicone-hydrogen Addition Reaction

Vinyl group can realize silicon-hydrogen addition reaction

Before Buying Silicone Resin, What Factors Should Be Considered ?

Due to the differences in individual formulations, the selection of the matching resin often requires reference to many aspects.

Application

The first thing to consider is your product application as a way to choose a resin with different properties.

Conditions

Such as: heating temperature, required film thickness, etc. The more detailed information, the more accurate the advic.

With solvent

Resin powders usually need to be used with a solvent, and the results will vary depending on the solvent you use.

Have you used resin before?

If you can provide MQ resin brand which you have used before, we can help you choose the resin with the same effect faster.

Why Choose XJY Silicones ?

As one of the top 3 experienced VMQ silicone (vinyl methyl silicone) factories in China, XJY SILICONES offers clients a wide choice of standard and customized VMQ silicone polymers with various specifications to meet the individual needs of each customer.

Your Reliable VMQ Silicone Resin Manufacturer In China

Benefit from the following manufacturing advantages:

Certified by ISO9001, REACH, RoHS, SGS certificates.

Pre-production samples for all orders before production starts

Experienced engineers to monitor the entire production process

Stable after-sales service

24-hour warehousing service and logistics support

Wholesale and retail experience

Quality control, including raw material incoming inspection, process intermediate product inspection, finished product factory full analysis inspection

Some Feedbacks

What Our Clients Are Saying ?

We Have Great Answers

Frequently Asked Questions

The MQ resin of vinyl silicone oil carries out hydrosilylation reaction with hydrogen-containing silicone oil, which can play the role of chemical reinforcement. The reinforced silicone rubbers are colorless, transparent and improve poor tensile strength, abrasion resistance.

The special structure of vinyl MQ resin is added through the vinyl groups and hydrogenated silicone oil to form a silicone rubber structure. At the same time, because of its special structure and functional group content, the silicone rubber maintains good strength colleagues and has an ultra-low hardness, forming a gel structure applied in food and medical industries.

It can also be used to shell-less packaging and insulation protection of optical fiber coatings and electronic components. And can modify other polymer resin to improve their hydrophobicity, weather resistance, temperature resistance, relatively low tear strength.

Our products are available in different molecular weights, vinyl contents and viscosities, which can be selected according to your application.

Under each product there are also our recommendations for the suitable application.

If you are still unable to choose, please contact us with your requirements and we will help you select the best product.

Of course, you can always contact us to get the materials and information you want. You can also download them through the specific product pages.

According to TDS and MSDS, it should be stored at or below 25℃ in the original unopened containers.

Regular stock products usually only need 7-15 days to stock, custom products are subject to availability, please contact us.

When stored at or below 25℃ in the original unopened containers, this product has usable life of 12 months from the date of production.

If more than the storage period, the product should be rechecked.

- The MOQ for regular products is one durm.

- For custom products, it depends on the situation, please contact us for your questions.

More Related Products For Your Reference

Smarter ways provide more options and solutions for your products to get more competitive

Silicone MQ Resin

Silicone MQ resin is a unique structure of three-dimensional spherical resin formed by the co-hydrolytic condensation of a silicone compound containing a tetrafunctional siloxane bond and a silicon compound having a monofunctional siloxane bond.

Hydrogen-containing Silicone Oil

Hydrogen-containing silicone oil contains a certain number of relatively active Si-H bonds in the molecule, easy to cross-link reaction, generally colorless or slightly yellow transparent liquid.

Silicone PSA

Silicone Pressure Sensitive Adhesive (SPSA) is a special adhesive composed of silicone resin (commonly used MQ silicone resin), silicone rubber, catalyst, crosslinking agent, and other additives.

Request A Free Quote

Don’t hesitate to contact us. XJY SILICONES’s product specialists are very happy to help you and provide a variety of flexible and reliable solutions to help you solve various problems.

- (0571) 8353 8273

- info@xjysi.com